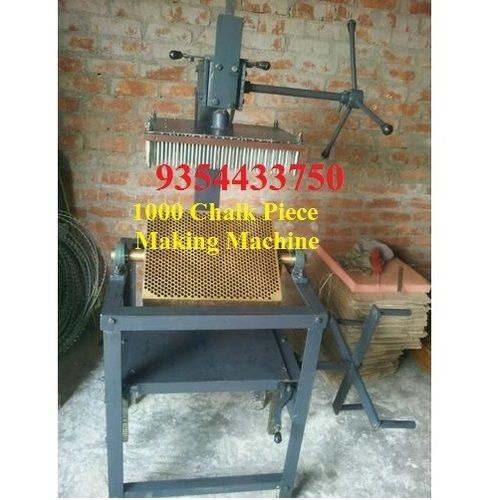

Automatic Chalk Making Machine

MOQ : One Machine Piece

Automatic Chalk Making Machine Specification

- Features

- Low maintenance, easy operation, robust build

- Machine Type

- Chalk Making

- Drive

- Electric Motor Driven

- Connectivity Options

- No connectivity/Standalone

- Frequency

- 50 Hz

- Noise Level

- <75 dB

- Power Rating

- 1.5 kW

- Motor Power

- 1.5 HP

- Voltage

- 220 V

- Lubricating System

- Manual/Oil Based

- Frame Type

- Mild Steel Fabricated

- Plastic Processed

- Calcium Carbonate & Plaster of Paris

- Accuracy

- High, uniform size output

- Control System

- Push Button/PLC Control

- Model No

- ACMM-100

- Production Capacity

- 5000-10000 pcs/8 hr shift

- Operating Temperature

- 10C - 40C

- Cooling System

- Air Cooling

- Product Type

- Automatic Chalk Making Machine

- Technology

- Automatic, Mechanical

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 1.5 kW - 2 kW

- Pressure

- Hydraulic, adjustable as per requirement

- Surface Treatment

- Powder Coated Frame

- Dimension (L*W*H)

- 1620 mm x 680 mm x 1200 mm

- Weight (kg)

- Approx. 400 kg

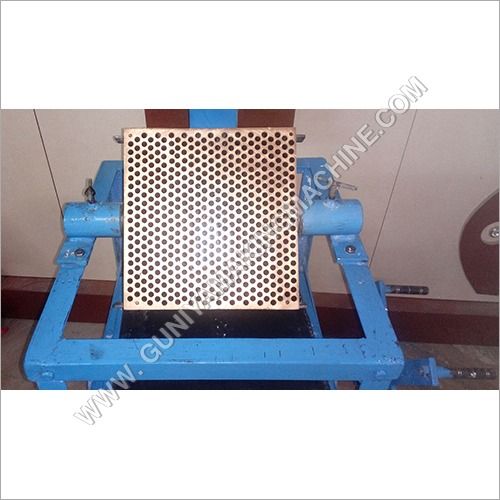

- Color

- Grey/Blue

- Usage & Applications

- Chalk stick manufacturing for schools, offices, industrial use

- Number of Mould Cavities

- Up to 400 per cycle

- Mould Material

- Aluminium Alloy

- Power Consumption

- Low, energy efficient

- Finish Type

- Smooth, Matt

- Safety Features

- Emergency Stop Switch, Finger Guard

- Chalk Size

- 8mm - 12mm diameter (customizable)

- Chalk Output Shape

- Cylindrical, Dust-Free

- Operation Mode

- Single/Double Line

- Installation Service

- Available

- Packaging Type

- Standard Wooden Box Packing

- Included Accessories

- Cleaning Rods, Mould Replacement Kit, Measuring Jar

- Input Raw Materials

- Plaster of Paris, Water, Color Pigment, Lubricant

- Working Speed

- 30-60 strokes/min

- Service Support

- On-site and Remote Support

Automatic Chalk Making Machine Trade Information

- FOB Port

- Wazirpur New Delhi

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Piece

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Automatic Chalk Making Machine

Experience a monumental leap in chalk production with the Automatic Chalk Making Machine, now at a reduced price for an ending soon offer. Packed with pivotal featureshigh production capacity (up to 10,000 pieces per shift), virtuoso precision, and a low-maintenance, energy-efficient designthis affordable solution delivers uniform, dust-free chalk sticks. Crafted from robust, powder-coated mild steel and equipped with aluminium alloy moulds, this machine supports both single and double-line operation with adjustable hydraulic pressure. Comprehensive safety mechanisms, installation service, and global support make it the perfect choice for educational, industrial, and commercial environments.

Unrivaled Advantage & Application Versatility

The Automatic Chalk Making Machine is engineered for high-speed, dust-free chalk stick manufacturing, ensuring smooth, matt finishes with every cycle. Designed for use on school, office, and industrial surfaces, it accommodates chalk sizes from 8mm to 12mm. Utilizing Plaster of Paris with color pigment, direction of use is straightforward: simply add raw materials, configure the push-button or PLC controls, and let the machines hydraulic system deliver consistent, high-quality chalk production with minimal manual intervention.

Swift Delivery, Secure Packaging & Wide Reach

Take advantage of the special sale price as machines are dispatched promptly via trusted transport services. Each unit arrives in standard wooden box packaging, ensuring robust protection during transit. Delivery times are minimized for main domestic markets, especially across India, making it convenient for exporters, manufacturers, and suppliers seeking reliable, efficient chalk production solutions. Every order is handled securely to keep your investment safe and ready for immediate installation upon arrival.

Unrivaled Advantage & Application Versatility

The Automatic Chalk Making Machine is engineered for high-speed, dust-free chalk stick manufacturing, ensuring smooth, matt finishes with every cycle. Designed for use on school, office, and industrial surfaces, it accommodates chalk sizes from 8mm to 12mm. Utilizing Plaster of Paris with color pigment, direction of use is straightforward: simply add raw materials, configure the push-button or PLC controls, and let the machines hydraulic system deliver consistent, high-quality chalk production with minimal manual intervention.

Swift Delivery, Secure Packaging & Wide Reach

Take advantage of the special sale price as machines are dispatched promptly via trusted transport services. Each unit arrives in standard wooden box packaging, ensuring robust protection during transit. Delivery times are minimized for main domestic markets, especially across India, making it convenient for exporters, manufacturers, and suppliers seeking reliable, efficient chalk production solutions. Every order is handled securely to keep your investment safe and ready for immediate installation upon arrival.

FAQs of Automatic Chalk Making Machine:

Q: How does the Automatic Chalk Making Machine operate?

A: The machine operates using a semi-automatic mechanism, driven by an electric motor. The operator loads the moulds with raw materialsPlaster of Paris, water, pigment, and lubricantand uses push-button or PLC controls. The hydraulic system forms uniform, cylindrical chalk sticks, ejecting them after each cycle.Q: What safety features are integrated into the machine?

A: This model includes an emergency stop switch and a finger guard to prevent accidental injuries, making it safe for use in various production environments. Additionally, the robust build and dust-free system contribute to a safer, cleaner workspace.Q: When should mould replacement or maintenance be performed?

A: Regular maintenance is recommended after every production shift, with mould replacements as needed depending on output volume and observed wear. The included mould replacement kit and cleaning rods make the process easy and efficient.Q: Where is the Automatic Chalk Making Machine commonly used?

A: The machine is ideal for chalk manufacturing in schools, offices, and industries. It is widely utilized by exporters, manufacturers, and suppliers throughout India and can also be deployed in other regions requiring large-scale chalk production.Q: What are the benefits of using this machine over manual methods?

A: Key benefits include higher accuracy in chalk size, dust-free output, energy efficiency, lower noise levels, and significantly increased production ratesmaking it a more effective, cost-saving alternative to manual chalk making processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in School Chalk Making Machine Category

School Chalk Making Machine

Minimum Order Quantity : 1 Piece

Product Type : Other, School Chalk Making Machine

Operating Type : Other, SemiAutomatic

Power Source : Other, Manual

Color : Blue / Green

Usage & Applications : For manufacturing dustless school chalk

Dustless School Chalk Making Machine

Minimum Order Quantity : 02 Pieces

Product Type : Other, Dustless School Chalk Making Machine

Operating Type : Semi Automatic

Power Source : Electricity

Color : Blue

Usage & Applications : Industrial

Chalk Making Machine

Minimum Order Quantity : 1 Pack

Product Type : Other

Operating Type : Semi Automatic

Power Source : Other

Color : Blue, Silver

Usage & Applications : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS