School Chalk Making Machine

School Chalk Making Machine Specification

- Plastic Processed

- Plaster of Paris (POP) used for chalk

- Frame Type

- Mild Steel, Welded Frame

- Production Capacity

- 400-600 pieces/hour

- Accuracy

- Consistent shape and size

- Machine Type

- Manual/Hand Operated

- Operating Temperature

- Ambient

- Cooling System

- Air cooled (Natural)

- Noise Level

- Low

- Control System

- Manual lever control

- Drive

- Manual Lever

- Model No

- SCMM-01

- Features

- User-friendly design, easy maintenance, robust construction

- Lubricating System

- Manual

- Product Type

- School Chalk Making Machine

- Technology

- Hand Operated

- Power Source

- Manual

- Operating Type

- Semi-Automatic

- Power

- Not Required for manual operation

- Pressure

- Manual pressure operation

- Surface Treatment

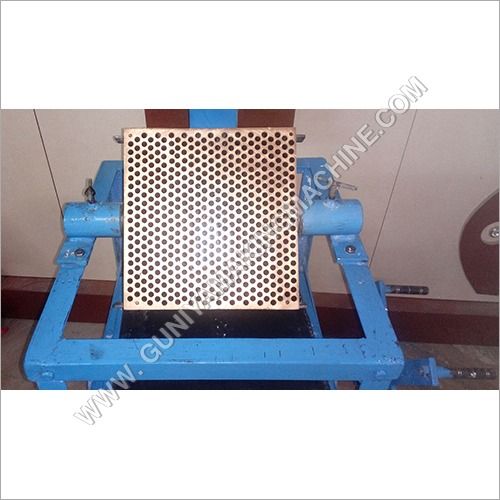

- Paint Coated

- Dimension (L*W*H)

- Approx. 2.5 ft x 1.5 ft x 2 ft

- Weight (kg)

- 35 kg (approx.)

- Color

- Blue / Green

- Usage & Applications

- For manufacturing dustless school chalk

- Required Personnel

- Single operator

- Corrosion Resistance

- Yes

- Chalk Type

- Dustless, white

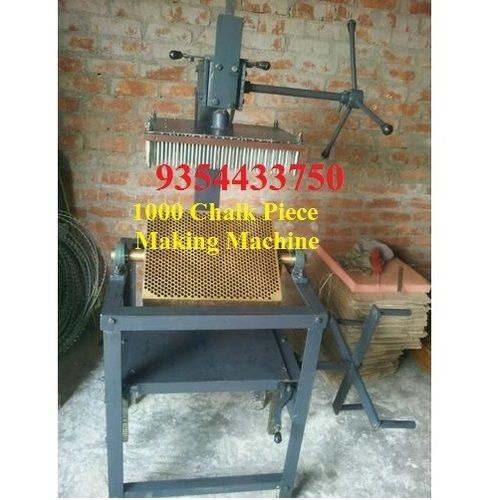

- Mold Cavities

- 40 cavities per cycle

- Chalk Size Range

- 7cm (standard length), customizable

- Cleaning System

- Easy dismantle for cleaning

- Material Used for Frame

- Heavy duty MS (mild steel)

- Production Cycle Time

- 5-7 minutes per batch

- Installation Service

- Available upon request

School Chalk Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 7 days Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About School Chalk Making Machine

Owing vast experience in the domain, we are manufacturing and supplying a exquisite range of School Chalk Making Machine. These machines are manually processed and no power require to operate these machine This machine is built by master engineers who utilize most recent innovation to make the machine. We never compromise with the machine quality which is the our standard in the market. Our customer can profit chalk making machine in various size and plan according to his prerequisites as we have scope of machine 500 limit in one time, 700 limit in one time and 1000 limit in one time. In our machine the procedure to make the school chalk is extremely straightforward and exceptionally smooth. Our customer can make up to 6 operation in one hours. Our School Chalk Making Machine is exceptionally plan for the dustless school chalk fit as a fiddle which is the exceptionally requested the market and we outline the structure of the machine like our customer need sliding sort machine or stand sort machine. Additionally, we outline spout stick like in gunmetal, aluminum, or ms. Also, we give a demo or preparing system to our customer after request affirmation up-to 2 hours to making the school chalk.

Features:

- Machine Type:- Manual operated School chalk making machine

- Size of chalk:- Size of chalk normally 75-80mm in length and top diameter 9.5mm and bottom diameter is 10mm

- Production Capacity :- up to 6 operation in one hour depend on worker.

- Molds:- we provide a gunmetal molds only.

- Used for :- Our client can make ordinary chalk, semi dustless chalk or Dustless white school chalk

Robust and Efficient Chalk Production

Designed for heavy-duty use in schools and educational supply manufacturing, this manual chalk making machine boasts a sturdy welded frame and a reliable manual lever control system. Its 40 mold cavities per cycle provide substantial output while ensuring uniformity and smooth surfaces in each chalk stick.

User-Centric Design and Easy Maintenance

The machines easy dismantle system saves time during cleaning, contributing to hygienic and efficient operations. The carefully designed manual lubricating and air-cooled systems ensure smooth performance, and a single operator can manage its functions effortlessly, making it practical for small-scale to medium enterprises.

Customization and Durability

Each machine can produce standard 7cm chalk sticks, with options for size customization based on requirements. The mild steel frame, painted for extra corrosion resistance, ensures a lengthy operational lifespan even in demanding environments. Its compact build (2.5 ft x 1.5 ft x 2 ft) makes placement flexible for different facility sizes.

FAQs of School Chalk Making Machine:

Q: How does the school chalk making machine operate?

A: The machine is hand-operated with a manual lever control, making it highly efficient without the need for electrical power. An operator simply prepares the plaster of Paris mixture, pours it into the 40-cavity mold, applies manual pressure, and waits 57 minutes for each batch.Q: What materials are used in the construction of the machine?

A: The frame is constructed from heavy-duty mild steel, welded for durability and painted to resist corrosion. The machine is designed for robustness and longevity, even with frequent use.Q: Where can the machine be installed, and is installation support provided?

A: This compact unit (approximately 2.5 ft x 1.5 ft x 2 ft) can be set up in classrooms, workshops, or small manufacturing spaces. Installation services are available upon request to ensure proper setup and operation.Q: What is the cleaning process for the machine?

A: The machine features an easy dismantle system, allowing operators to quickly take apart and clean all contact components. Regular cleaning prevents chalk residue buildup and maintains product quality.Q: Who is this machine suitable for and what are its primary benefits?

A: School supply manufacturers, small business owners, and exporters seeking an efficient, user-friendly, and low-maintenance solution for producing dustless chalk will benefit most. The machine offers high production capacity, strong build quality, and minimal operational costs.Q: What is the production capacity and accuracy of the machine?

A: With 40 cavities per cycle and a 57 minute batch time, the machine can produce 400600 chalk sticks per hour. Its consistent molding process ensures uniform shape and size in every piece.Q: When should maintenance be performed on the chalk making machine?

A: Routine cleaning and lubrication after every few production cycles are recommended to ensure smooth operation and longevity. The easy dismantle system makes this process straightforward for the operator.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in School Chalk Making Machine Category

Automatic Chalk Making Machine

Minimum Order Quantity : One Machine Piece

Power Source : Other, Electric

Operating Type : Other, SemiAutomatic

Usage & Applications : Chalk stick manufacturing for schools, offices, industrial use

Color : Grey/Blue

Product Type : Other, Automatic Chalk Making Machine

Dustless School Chalk Making Machine

Minimum Order Quantity : 02 Pieces

Power Source : Electricity

Operating Type : Semi Automatic

Usage & Applications : Industrial

Color : Blue

Product Type : Other, Dustless School Chalk Making Machine

Chalk Making Machine

Minimum Order Quantity : 1 Pack

Power Source : Other

Operating Type : Semi Automatic

Usage & Applications : Industrial

Color : Blue, Silver

Product Type : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS